Control Simulator Haas Automation

VPS is Haas Automation''s proprietary conversational programming system that uses simple, stepbystep templates and 3D graphics to help the user quickly .

WhatsApp)

WhatsApp)

VPS is Haas Automation''s proprietary conversational programming system that uses simple, stepbystep templates and 3D graphics to help the user quickly .

Step 1: Video of Using a Manual Milling Machine This video will show you how to use a Manual Mill and explains the different parts to know to use it properly. On the next slide, I will show a close picture on the different parts of the machine to have an idea what I was using on the video.

Stair climber machine, step mill, StairMaster, stair stepper machine, stair workout machine, step machine, step climber—there are tons of names for this machine. It became a fan favorite after being introduced in the 1980s due to its low impact nature. It''s also popular due to its ability to increase both endurance and stamina.

Mar 31, 2014· How to Use steps() in CSS Animations. CSS3 • Tutorials Joni Trythall • March 31, 2014 • 6 minutes READ . I am guessing that many of you have found steps() to be confusing when using it in CSS animations. I wasn''t sure how or why to use it at first and searching seems to produce two main examples: A typing demo by Lea Verou and an animated sprite sheet by Simurai.

The last step is to drill and countersink the mounting holes. Actually, I wasn''t completely truthful. Once you have mounting holes, the last step is to mill a step along each jaw, maybe 1/8″ square. Now you can use that step instead of parallels when you drop material into the vise.

May 18, 2017· Vertical Axis Wind Turbines. Vertical axis turbines work as efficiently no matter which direction the wind is blowing. There are several styles of vertical axis turbines. Darrieus (aka ''eggbeater'') turbines, use blades shaped like airplane wings in crosssection, using the lift to move them horizontally.

How to Properly Load an End Mill Into a Vertical Mill: Okay folks, this is just a quick tutorial on mounting that end mill (or other cutter, etc) into an R8 collet in the mill, and getting it gripped correctly to prevent damage to your cutter, collet, workpiece, your face, your buddies face, etc. Ther...

A stair stepper cannot calculate the number of flights solely based on the number of steps you take. Unlike a step mill, a stair stepper does not have a set step with a predetermined height. Depending on the specific model, a stair stepper machine allows for a step between one and 14 inches.

Sep 01, 2019· Learning to use a treadmill requires many of the same principles of training that runners use to prepare for races. You must increase your stamina gradually, in order to avoid injury, dizziness and problems with blood pressure or dehydration. Find out how to use a treadmill by following this stepbystep .

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operations.

How to Set Up CNC Milling Machine. Now come to the setting up machine, although every CNC Milling machine setup procedure is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine.

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same.

Step 1. Define the most important views and place the relevant orthographic in the center of the drawing, leaving enough space between them to add dimensions. Step 2. If your part has internal features or complex and difficult to dimension areas, consider adding section views or detail view accordingly. Step 3. Add construction lines to all views.

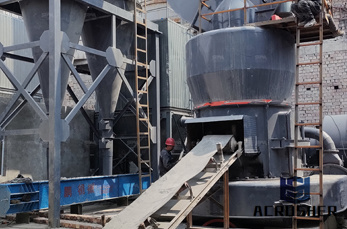

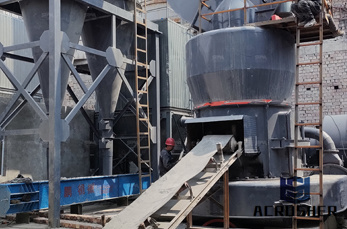

VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry mills. With a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and ...

Oct 12, 2016· Make sure the alignment of the blade is correct by using a 90degree mark. The blade should be perpendicular to the table. Set the miter guides to help keep the wood stock in place. Use a pencil to draw the lines you will use to cut the wood piece. Clear the work area so that you can move the wood piece freely. Plug your machine up.

How to use VLOOKUP in Excel Step 1: Organize the data. The first step to effectively using the VLOOKUP function is to make sure your data is well organized and suitable for using the function. VLOOKUP works in a left to right order, so you need to ensure that the information you want to look up is to the left of the corresponding data you want ...

Modern vertical milling machines are designed so the entire head can also swivel to permit working on angular surfaces. The turret and swivel head assembly is designed for making precision cuts and can be swung 360° on its base. ... Adjustable step blocks are extremely useful to raise the clamps, as the height of the clamp bar may be adjusted ...

If you plan to risk it move the Vertical Milling Machine yourself, use these simple steps below to move your vertical milling machine safely and securely. Pick up the Vertical Milling Machine under the Ram. This can be done from the sides, the front, or the back of the Vertical Milling Machine. Loading from either side (Recommended)

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

Feb 03, 2020· Although every CNC milling machine set up will be slightly different, these are the generic steps I follow on a daily basis for a 3 axis vertical CNC milling : I am assuming you know some basic machining practices. For example, how to use an edge finder, how to navigate through your machine''s control, and knowledge of basic CNC ...

Jul 07, 2014 These instructions contain detailed steps about how to use a Bridgeport Series 1 vertical 2 axis mill with TRAK 2 axis control. Although this set of instructions pertains to a particular type of mill, a lot of the steps that are described here can be applied to other Bridgeport Series 1 milling

JET Vertical Milling Machines are manufactured for precision, reliability and durability. Table sizes ranging from 8" x 36" to 12" x 54" and drivetrains of step pulley, variable speed, and electronic variable speed allow for easy mill selection. Include installed accessories such as powerfeeds, digital readouts, or a power draw bar to ...

The first few times you use a treadmill, you may feel dizzy when you step off. Your body is just wondering why the ground suddenly stopped moving. Don''t worry. Most people only experience this vertigo once or twice. Never go barefoot. Always wear a good pair of walking or running shoes for your treadmill workout. Don''t read while on the ...

WhatsApp)

WhatsApp)