Five iron ore trends to watch in 2020 – report

Metals and mining research and consultancy group Wood Mackenzie has identified five trends that will impact the iron ore industry in 2020. Slower demand growth, especially in China, and a decent ...

WhatsApp)

WhatsApp)

Metals and mining research and consultancy group Wood Mackenzie has identified five trends that will impact the iron ore industry in 2020. Slower demand growth, especially in China, and a decent ...

The midsized company JOEST + Co. KG from Duelmen in Germany is installing a hightech system for processing iron ore pellets in Narvik,, the northernmost city of Sweden, is home to an iron ore mine of the same name, which processes and stores pellets.

Jun 06, 2016· Mining Iron Ore Technical 3D Animation / IR PR Presentation Kostanay Kazakhstan KazaX Minerals Inc. Duration: 3:39. ImageMaker Advertising Inc. 26,749 views

Iron mining in the United States produced million metric tons of iron ore in 2015, worth US billion. Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and of the iron ore was mined in northern Minnesota''s Mesabi Range.

Iron Ore Pellets Screening Solutions The size distribution of iron ore pellets is among the most important quality parameters for the end users of those pellets, the steel mills. The tighter the distribution is, the better the performance and energy efficient the steel making process will be.

Projects – Iron Ore MAX Plant Projects Knowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment. From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to [.]

Mining not every company is able to help investors design build one available mining production line fortunately you find zenith we are experienced in mining and we have complete set of mining,Mining vibrating feeder for iron ore gold ore copper ore feeding .

Pfister Feeder – bulkonline Forums. If the term "Pfister feeder " means a Rotor scale . I represent a company Called Clyde Materials Handling, . my cement plant is using Pfister weigher for coal

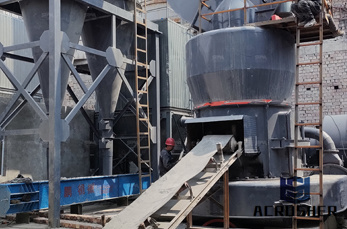

Iron ore mining Working with Iron Ore industry to improve recovery. Schenck Process has been active in iron ore mining for more than 20 years by providing its special separation and vibrating solutions to enhance the iron ore recovery rate.

Automatic ore feeders are used to eliminate hand feeding of material into the stamp battery. The Challenge ore feeder has an iron hopper that collects ore from the ore bin. Under the hopper is a circular table inclined toward the stamp battery mortar which slowly revolves.

Equipment for the Mining Minerals Processing Industries. Eriez is your goto resource for the latest and most advanced equipment and solutions utilized in minerals processing. We are the leaders in a wide variety of mining applications, including Industrial Minerals, Iron Ore, Coal Processing and Hard Rock Mining.

Find many great new used options and get the best deals for Rogers Iron Works Company Joplin MO Vintage Photo RokOre Apron Feeder Mining at the best .

May 04, 2012· The hopper had to fit a certain capacity of iron ore and the feeder needed to reflect the movement style of larger ''onsite'' feeders. Solution. designed and manufactured the hopper and frame as per the specifications outlined by FMG. The feeder used a concentrated sub resonant design to mimic a full sized sub resonant feeder.

Iron ore is an ore always in demand, due to its use in producing iron and steel bars via Smithing. There are many locations to mine iron ore, but one of the best members'' places to mine iron for banking is Ardougne Monastery. It has six iron rocks total that are all very close to each other...

The Plunger Ore Feeder includes a strong cast iron frame supporting a small welded steel hopper, and the plunger bearing. The unit is built so that a feed chute can be easily attached to the discharge opening. The stroke is adjustable and can be regulated easily. These ore feeders are low priced and recommended for small tonnage.

Used before primary crushers, wobbler feeders excel where others fail – in situations too wet and sticky for other feeders and scalpers. This is made possible by their selfcleaning and nonclogging elliptical bars, which allow material to be fed and separated without blinding.

Coarse Ore Feeders can roughly he classified into two groups, those that handle coarse ore, rock that is destined to become feed for the crushing department. And those that handle the fine ore, material that is finished being processed by the crushing plant. The different types of feeders that handle the coarse ore are, Ross feeder, pan feeder, vibratory feeder, apron feeder, and finally a ...

Nov 21, 2014· Iron ore mining is a very complex procedure though it has been perfected over the last few centuries to make it more efficient and less labor intensive by the use of giant earth moving machines. Open pit mining is used for the production of iron ore.

iron ore mining apron pan feeder drag chain conveyor iron ore mining apron pan feeder drag chain conveyor is widely used in building materials, metallurgy, electric power, coal, chemical, foundry and other industries, especially suitable for transporting some of the high temperature, blocks of large, with sharp edges and abrasive strong solid material.

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

Vibrating feeder No easy task When medium, heavy or extremely abrasive materials have to be transported over different conveyor lengths from silos or other storage containers.

Sep 25, 2012· A major iron ore mining operation in Africa, commissioned Don Valley Engineering to design and build a bespoke, large and robust belt feeder. The feeder is designed to handle iron ore tailings of 2100 Kg/M3, and to provide 365 days per year continuous operation. "We were selected to work with the client on the basis of our long history [.]

Oct 08, 2011· Iron Ore mining in the Plibara region of Western Australia near Newman. The Mt. Whaleback, Yandi, and Area C mines are shown. Iron Ore mining in the Plibara region of Western Australia near Newman ...

Mining feeders for productive processing. Today''s mines often run automatically, with longer hours and fewer personnel, and they require equipment that can reliably handle material day in and day out.

WhatsApp)

WhatsApp)