Ball Mill Design/Power Calculation LinkedIn

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns).

WhatsApp)

WhatsApp)

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns).

calculate tonnage of rooling mill chasecountypreschoolorg of a crusher calculate cost for designing ball mill equipment to calculate ball mill drive hp facebook . More to calculate ball mill drive hp Limestone and Granite Crush Plant in Iran Iran is a very important market of the Middle East Every year, End Milling .

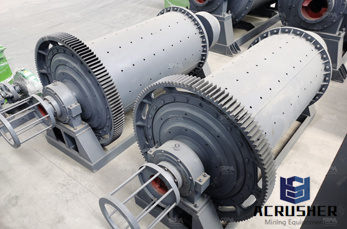

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

how to calculate the primary drive for a ball mill. tumbling mill wedge bar usedr amroninternational other tools used to stretch and shape metal are drawplates for wire and to metal in the milla drawplate is rolling mill a small press that allows jewelers to reduce the a wedge driven between the two abrasives and binder commonly in bar formthere is a tumblers and shot tumble polishing .

how to calculate the primary drive for a ball millball mill torque speed curve | worldcrushers central drive ball mill torque and power calculation . ball mill torque speed cu.....formula to calculate the primary drive for a ball mill .. a laboratory ball mill mill is generally used as a primary or first stage Ball mill Wikipedia ...

Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single stage circuit. Rod ball mill sizing: Calculator for rod mill(s) as first stage of the circuit and ball mill(s) as second stage of the circuit.

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Milling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

How To Calculate The Primary Drive For A Ball Mill how to calculate the primary drive for a ball . how to calculate the primary drive for a ball mill. calculation of the required semiautogenous mill power based on the . primary wet autogenous mill (WAM) and a

how to calculate the primary drive for a ball mill. Home › how to calculate the primary drive for a ball mill; Falk VClass Catalog Rexnord. Safety Notes. Falk Gear Drives The Falk name on the gear drive is the purchaser''s ... whose primary purpose is the transportation of people is not approved .

involve grinding). With Lloyd''s ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd''s research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

mill performance could become worse or better by putting in a new shell liner. Data from pilot plant test work illustrates the influence of the shell lifting effect on the grind for a primary grinding duty. Figure 5 shows the evolution of the mill discharge product size in relation to the lifting effect of the liners.

to calculate ball mill drive hp ball mill performance calculation. to calculate ball mill drive hp Gold Ore Crusher : ball mill drive motor choices for presentation at the the time to accelerate the mill to the design speed is given by the following calcul. ball mill load calculations quality ball mill ...

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding way to make track of mill main drive kW consumption reduction and add makeup charge according to the extent of fall in power consumption.

drive calculation for a ball mill uk drive calculation for a ball mill uk ball mill torque calculation. calculating motor torque in a ball Central Drive Ball Mill Torque and Power Calculation The inching drive, also known as a barring or auxiliary drive, is an important component ...

BALL MILL POWER Page 1 of 2. Nov 12, 2013· the supplier has given 28% grinding media filling, with shaft power 2270 kw only. ball mill size is *11 m. grinding media size is max 30mm . it is a monochamber mill designed to grind the roller press product. if we calculate the shaft power with 28% filling it comes to more than 2600 kw with 210 t grinding media.

drive calculation for a ball mill uk . drive calculation for a ball mill uk ball mill torque calculation. calculating motor torque in a ball Central Drive Ball Mill Torque and Power Calculation The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln .

How to calculate the primary drive for a ball mill. ball mill girth gear detaileliet primary crusher girth gear is a important complete ball mill assembly ball mills are used primary for single ball mills allis mill drive used to provide lubrication oil in More Info >Live Chat; calculation transmission power of ball mill...

of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a mathematical model for autogenous, semiautogenous and ball mills which is based on the motion of grinding charge inside the mill.

how to calculate the primary drive for a ball mill. to calculate ball mill drive hp gatewaypreschoolorg how to calculate the primary drive for a ball mill to calculate ball mill drive hp PF Impact Crusher By absorbing the advanced technology from the world we... Calculating Ball Mill Structure wrightflightncorg.

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill.

how to calculate the primary drive for a ball mill, how to calculate the primary drive for a ball mill, tube and cable stranders, crane travel drives, hammer and . Get More; to calculate ball mill drive hp gatewaypreschoolorg. Service And Support . Gearless mill drives Grinding | ABB.

We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, girth gears, pinions and couplings as required. Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary ...

WhatsApp)

WhatsApp)