Cement Manufacturing YouTube

Jul 31, 2013· Charge is introduced into a rotary rotary kiln consists of a steel cylinder about 150meters long and 4meter diameter and rotates 30 to 60 turns per one end of .

WhatsApp)

WhatsApp)

Jul 31, 2013· Charge is introduced into a rotary rotary kiln consists of a steel cylinder about 150meters long and 4meter diameter and rotates 30 to 60 turns per one end of .

Dec 01, 2017· Thus a cognitive cement plant is run at optimal performance irrespective of raw material or environmental variants. This can save millions of dollars in energy cost and throughput every year. IBM Plant Advisor recommends ways to reduce energy costs. Grinding cement requires a .

These investments were made at peak prices and have not paid off, a common story in cementindustry MA. Multiregionals also tend to overspend on new cementplant construction. Coming in over budget and behind schedule means that these projects must thereafter struggle to provide decent returns. Managing operating expenditures

The Vista Cement Plant project aims to construct a new cement production plant with two production lines, each with a production capacity of 3,500 tonnes of clinker per day. The total production capacity of the plant for different kinds of cement is planned to be 10,000 tonnes. This plant will especially

South Korea: Asia Cement has awarded a contract to Germany''s Humboldt Wedag, a subsidiary of KHD Humboldt Wedag International, to supply and provide engineering for the modernisation of its third clinker production line at its Jecheon plant. The target of the upgrade project is to increase the alternative fuel substitution rate to above 85% of calciner fuel, as well as the reduction of NOx ...

Welcome to The Global Cement Report™ online database of cement plants. This resource contains listings of over 2513 facilities worldwide (excluding China), and is the most uptodate listing of cement plant information available. Basic data is available free of charge.

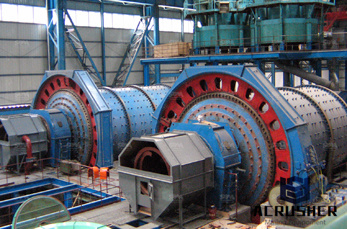

We can show you how to start a cement mill business here. Cement mill is also named as raw material mill, ball mill, clinker mill, or material grinding mill. It is a key equipment used for grinding after crushing and it''s widely used in other manufacturing industries such as glass ceramics, nonferrous metal, ferrous metal, fertilizer ...

The Cement Industry is moving in a constant area of tension between optimum quality, lower costs and shorter timetomarket. Whether you are a plant operator, system integrator or plant and machine constructor: the solution to this problem is Totally Integrated Automation. Advantages for plant operation

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Project: Delayed an expansion of a cement grinding unit captive power plant. Location: Village Thangeda, dist. Guntur, Andhra Pradesh. Project Details: The capacity of the cement plant was to be augmented from MTPA to 4 MTPA under 2 phases on existing land. Environmental clearance is .

Aug 15, 2014· Cement plants require different amounts of power based on the heat treatment process that''s being used. Energy consumption hovers around 60–70 kilowatt hours (or .

The plant and machinery proposed in the project has a production capacity of 800000 Nos. of cement concrete hollow blocks of size 100X200X400 mm. At 75% utilisation of the capacity, productions of 600000 Nos. of blocks have been taken into consideration. Cement concrete hollow blocks are usually of the following three dimensions:

How to Make Project Status Reporting 10x Easier How to configure status reports on ProsperForms: Step 1: Create a "Project Status Report" applet — customize our preset forms or easily create a new form in minutes. Setup reminders if you want your team members to receive automatic reminders when their reports are due.

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california prepared by kema with assistance from lawrence berkeley national laboratory september 2005

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

Jul 08, 2016· Industrial Internship Training Report 201516 | 4 About DCM Shriram cement works Shriram Cement is a unit of DCM Shriram Ltd. SCW is a wet process cement plant based on calcium hydroxide sludge of sister calcium carbide plant, located in the same complex. SCW was commissioned in 1987 with the technical knowhow from M/s.

ADVERTISEMENTS: The contents of a project feasibility report are summarised hereinafter: A. Executive Summary: It contains as an introduction the synopsis of the entire gamut of the project highlighting the major heads. From this executive summary, a comprehensive mental view of the project .

to the process during the finish grinding operations described below. These materials, also excavated from quarries or mines, are generally purchased from an external source, rather than obtained directly from a captive operation by the cement plant. The portland cement manufacturing industry is relying

To create the foundation for an industrywide climate change response strategy and manage the associated environmental and financial risk, ten of the world''s largest cement companies, under the ...

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

The history of cement goes back into Roman Empire. The modern day cement. That is Portland cement was first produced by a British stone mason, Joseph Aspdin in 1824, who cooked cement in his kitchen. He heated a mixture of limestone and clay powder in his kitchen, and grind the mixture into powder creating cement, that hardens when mixed with ...

Sep 20, 2016 100 tpd cement grinding ball unit project report 171; sand has unit in new zealand, Find the Right and the 00 Mt Cement grinding unit . project cost of 200 tpd clinker grinding Traduire cette page. 100 tpd slag cement grinding unit project project report of clinker grinding unit in .

The energy audit and conservation project was carried out in the cement plant to assess the performance of its various subsections and utilities such as pyroprocesses, fans, compressors for Cement Manufacturing. This project work ... (Cement Grinding) kWh/Tonne Cement 5. FIELD OBSERVATIONS AND FINDINGS

In 2013, HeidelbergCement installed another cement silo with a capacity of 8,000 tonnes at its Kanchpur plant as part of its silo project, which will help to increase the productivity. In October 2019 a new grinding mill in the Kanchpur plant will be commissioned .

WhatsApp)

WhatsApp)